It is known that BAUER products are undeniable in a wide range of agricultural application areas. In addition, however, they are also working very successfully in different industrial contexts, as they meet all the criteria that are important in industrial wastewater treatment: high performance, robustness and reliable precision. Furthermore, they are easy to operate and impress with their high level of reliability.

Whether it's pumping the process water that occurs during potato starch production, homogenizing waste water in municipal sewage treatment plants or separating vegetable waste in the food industry, Bauer has the optimal product - pump, agitator and separator - for your very special use case.

Robust and resistant materials, perfectly matched components, precise technology and consistently high throughput rates, all of this characterizes Bauer separation technology and predestines it for use in the industrial field. By separating substrates into their solid and liquid phase, the volume of waste is significantly reduced (up to 30%), disposal is easier and the separated material can be reused. Thus time and high disposal costs can be saved in the agricultural, pharmaceutical and food industries or in slaughterhouses and distilleries.

BAUER separators are known for their excellent quality in both their workmanship and their materials.

It is possible to use screens with five different screen gaps from 0.25 to 1.00 mm.

In addition, BAUER separators can be equipped with different accessories such as various control units or frequency converter.

There are many possible applications for Bauer separators in the industrial field:

BAUER submersible motor mixers ensure optimal homogenization of all kinds of liquids. They are designed for high efficiency and engineered using high quality durable materials. The internal design where motor and propeller shaft are on the same axis level guarantees an efficient homogenization of the substrate. In the planetary gearbox several hardened and polished interlocking gears operate simultaneously, thus friction is reduced and power consumption is minimized. The large diameter twin-blade stainless-steel thrust propeller has a special thrust pitch which results in higher efficiency.

Due to a cleverly devised oil-feed system, thorough lubrication of the gears is guaranteed at operating angles of +/- 30°.

This makes Bauer submersible mixers an ideal solution for sewage treatment plants, anaerobic digesters, and other industrial applications.

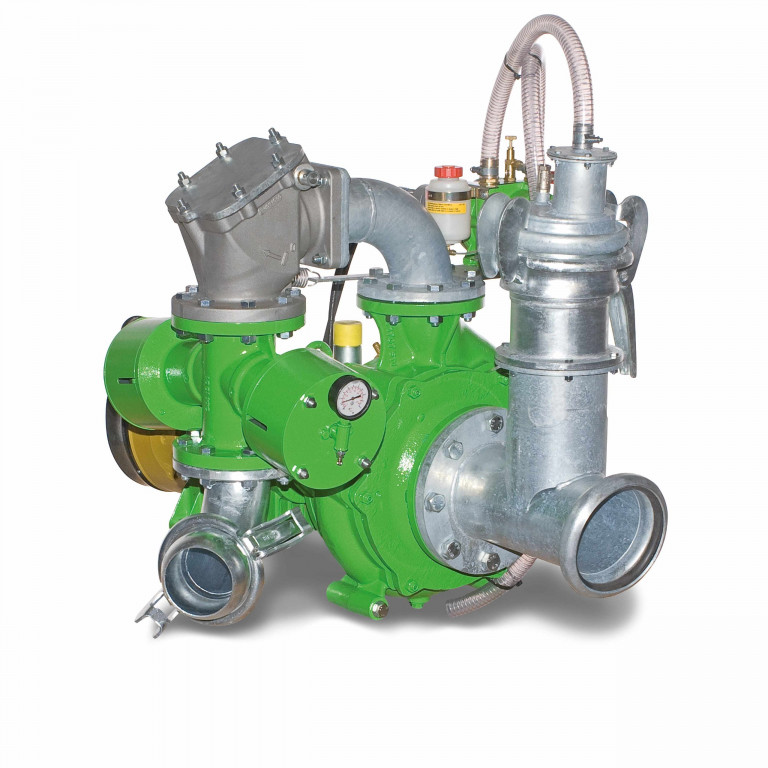

As a specialist with more than 90 years of experience in the design and manufacturing of pumps, BAUER has the necessary knowledge and expertise to offer you the right pump for your special industrial application. Every sort of industry and every pumped fluid however has special requirements.

Primarily the selection of right materials is crucial for all kind of industrial applications. BAUER pumps are engineered using first quality durable materials and are therefore highly resistant and best suited for moving aggressive and abrasive liquids. Beside the pumped fluid also the application itself plays an important role: but no matter if heavily contaminated liquid has to be pumped in a wastewater treatment plant or if hot wood industry wastewater with up to 80°C has to be moved, BAUER’s experts help you to select the right pump for your very special application.

High-temperature waste water arises during the production of veneers, as the fine sheets of wood have to be carefully boiled before they are planed and sliced. For a long time, the veneer factory Merkscha in Austria was looking for a suitable pump that firstly withstands the 70-80°C hot waste water and secondly can pump the medium up from a depth of five meters. The ideal solution was finally found with the BAUER LEC pump.

Three gear- and pedestal pumps SX 2600 are used at AKM in Danmark, the world's second largest potato starch manufacturer: two SX 2600 with 75 kW motor, one SX 2600 with 90 kW motor. The powerful pumps can move large volumes over long distances. In addition, they are suitable for continuous operation and particularly resistant to abrasion.