Contractors and farmers with high demands on technology and performance will find their individual slurry tanker in the professional pump tanker range. Quality and design, paired with your specific needs, will offer you an economical machine. We work with you to prepare your requirements profile, and we use this profile to manufacture a profi pump tanker that meets your operating conditions.

BAUER pump tankers in steel construction can hold up to 24,000 litres transport volume.

We use only certified top-quality steel plate of renown steel factories. The tanks are rolled, joined and finally automatically welded in diameters of 1100 mm - 2000 mm on our own production lines. All components such as tanks, anti-surge baffles, frames and drawbars are calculated and approved according to the strict Austrian guidelines.

Bauer pump tankers stand out due to fast filling, high spreading pressure and sturdy pumps. The high-quality standard equipment is complemented by a comprehensive range of accessories.

With the Bauer pump tanker, it is possible to regulate the application rate via the 3-way valve, the pump speed and the driving speed. The application rate can be regulated by adjusting the 3-way valve. High spreading pressure of the pump tanker guarantees large strip widths and a uniform slurry distribution.

Our experienced construction engineers develop new components and equipment focusing on well proven technology. BAUER slurry tankers are drawn in full 3D on CAD design workstations, ensuring that spare parts are available even after many years. Test runs and load tests make sure that every prototype is ready for series production.

Your confidence is based on our experience.

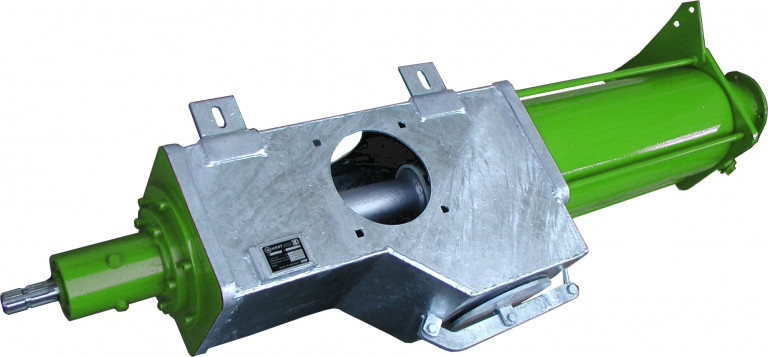

The Bauer eccentric rotor pump is characterized by its high performance data. The extra-large suction box for the tanker insert with a standard foreign body discharge flap protects the tanker from heavy foreign objects.

The pump rotor is manufactured at our own premises. The hollow rotor is made of high-grade steel in a special hot forming process. The low weight of the hollow rotor provides to the pump its smooth running. The whirling process makes the surface perfect, provides for a precise external geometry and a very smooth running surface. This is decisive for high output and low wear. The final surface-hardening serves to refine this perfect surface and to provide a long service life and good resistance.

The pump stator is manufactured at our own premises. A special rubber mix is vulcanized into a steel tube via an extruder. The recipe of rubber mix is appropriate for the use with both slurry and water on account of long experience and of today’s possibilities of materials. After the extruding process, the rubber geometry is hardened in an oil bath offering thus good wear resistance and hence a long service life.

This allows for a subsequent attachment of a spreading boom. Thanks to the serial flat manhole, the spreading device can be attached as closely as possible to the tanker body.

Fast, effective, clean. And without getting off the tractor. With a suction arm (automatic suction), you hydraulically dock the suction line into a suction funnel placed on the slurry pit/lagoon. Thanks to hydraulically controlled suction slides, you start/stop the filling process directly from the tractor. Different types of suction arms are available.

An electronic system detects the maximum filling level and pneumatically or hydraulically switches the slide valves from suction to repumping, thus preventing overfilling.

This vertical load upholding system (SLE system) automatically controls the filling level of the first tank chamber and always allows maximum drawbar load. The SLE system allows maximum traction on the tractor wheels, thus minimising any damage to the ground. Furthermore, it contributes to a much safer driving behaviour. No wear parts in the system allow for obstruction-proof operation, and the serial best stirring properties of the pump tanker are not affected.

The Edelweiss edition was designed specifically for pre-Alpine slopes:

The low design with the large wheel wells shifts the center of gravity downwards and keeps the tanker stable even on slopes. The generous tires of up to 30.5" ensure smooth running even on wet meadows and protect the soil. The tankers are available in dimensions of 7,000, 8,000 and 9,000 liters. As an added bonus, the proven SLE system is included as standard. Only maximum support load guarantees the best possible traction of the tractor tyres on the ground. Naturally, the Edelweiss line is also designed for spreading manure close to the ground. Trailing hose applicators in working widths of 6-10.5m, which can be retrofitted at any time, are ideal for this tanker series.

Our pump tankers are also available in tandem execution

Pump tandem tankers from 10,000 litres have been equipped with the proven 4-spring tandem unit for many years now. Sturdy suspended parabolic springs combined with the compensating rocker and, on large series, with additional longitudinal stabilisers provide driving safety and high load-bearing capacity. From size V100TL, a self-steering on the second axle is included as standard. This ensures low tyre wear and soil protection in the field.

Pump tandem tankers from 10,000 litres have been equipped with the proven 4-spring tandem unit for many years now. Sturdy suspended parabolic springs combined with the compensating rocker and, on large series, with additional longitudinal stabilisers provide driving safety and high load-bearing capacity. From size V100TL, a self-steering on the second axle is included as standard. This ensures low tyre wear and soil protection in the field.

Pumps of different capacity

Preparation for hose applicator / trailing shoe applicator: allows for a subsequent attachment of a spreading boom. Thanks to the serial flat manhole, the spreading device can be attached as closely as possible to the tanker body.

Fast, effective, clean! And without getting off the tractor. With a suction arm (automatic suction), you hydraulically dock the suction line into a suction funnel placed on the slurry pit/lagoon. Thanks to hydraulically controlled suction slides, you start/stop the filling process directly from the tractor. Different types of suction arms are available.

An electronic system detects the maximum filling level and pneumatically or hydraulically switches the slide valves from suction to repumping, thus preventing overfilling.

This vertical load upholding system (SLE system) automatically controls the filling level of the first tank chamber and always allows maximum drawbar load. The SLE system allows maximum traction on the tractor wheels - thus minimising any damage to the ground. Furthermore, it contributes to a much safer driving behaviour. No wear parts in the system allow for obstruction-proof operation, and the serial best stirring properties of the pump tanker are not affected.

Configure your own individual tanker from a wide range of tyre pressure regulators, the latest control technology and many other options.

The slurry tanker of tomorrow needs maximum flexibility in terms of equipment and retrofitting. With the AETOS tanker line, Bauer is anticipating the future and offering an all-round flexible tanker that can be tailored precisely to the requirements of the individual farm. The three tanker lines AETOS, AETOSMID & AETOSPRO offer a wide selection of options and thus a perfect configuration for any requirements. The Aetos series is equipped with a pendulum unit as standard, which has proven itself in the poly tankers already for decades. Most components – such as the EHLA electro-hydraulic positive steering, the fully automatic spreading quantity control, the NIR sensor, a tire pressure control system, the SLE system for tongue load retention, and more – can be easily retrofitted. And options for attaching spreading equipment are a given, of course. Of course, the tanker is prepared for attaching spreading equipment.