Contractors and farmers with highest demands on technology and performance will find their perfect slurry tanker in the professional polyester model range. Of stylish design, economical and unique: a BAUER poly tanker is a real eye-catcher and simply something special! More capacity at low dead weight enables easy application of your precious natural fertilizer in less rides. Contact us: We work with you to prepare your requirements profile, and we manufacture then a profi polyester tank that meets your operating conditions.

The Gelcoat coating ensures highest UV-resistance. This offers long and reliable durability. BAUER uses original Yachting Gelcoat with the technical characteristics of experts and a professional optics. Yachting Gelcoat offers a very smooth surface and therefore is easy to clean, especially when it comes to biogas slurry. Gelcoat provides utmost resistance against environmental influences and road salts.

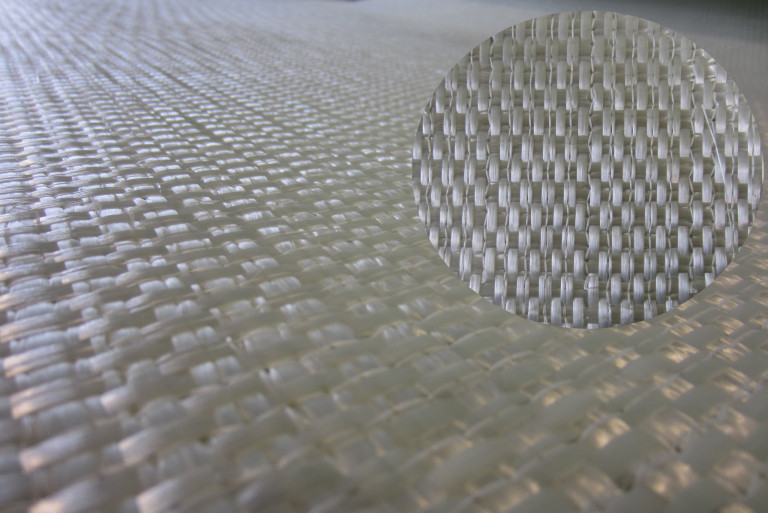

Due to its continuous fibre bundles, the Rowing fabric enables to derive static and dynamic forces from calculated points of the chassis.

= Longer service life

Development for the future

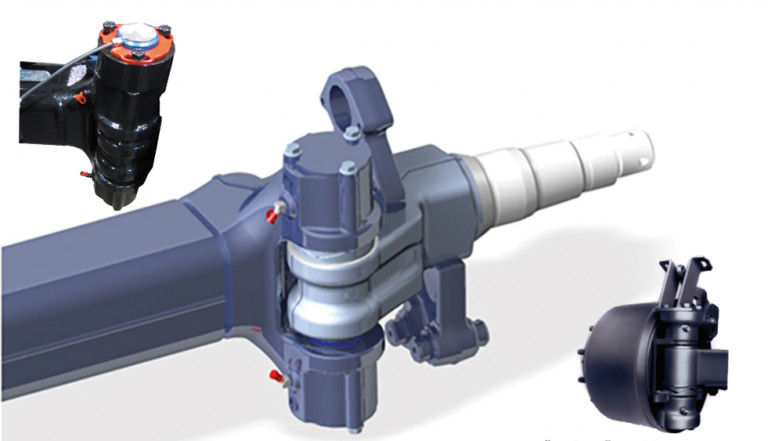

Faster, bigger, more efficient - today's demands on axle groups are enormous, making the BAUER tandem swinging axle group another centrepiece of every polyester tanker. The wheels swinging independently allow for an evenly distributed, low ground pressure. The integrated "AgroTurn" axle stub steering of the group produces smooth trailing behaviour due to the special thrust washer. The steering angle can be maximised depending on the tyre dimension. Therefore, this tandem steering group is also gentle on tyres. The solid bar geometry ensures low overall height and high load-bearing capacity as well as best field and slope characteristics.

The BPW AgroTurn steering axle allows for a bigger steering angle thanks to the new, forged steering fork.

In addition, the angle sensor of the forced steering is installed directly in the steering box of the “AgroTurn” steering axle so that it is protected against pollution.

The BAUER swinging axle group has already been prepared for forced steering as standard. Hence later modification from self-steering to forced steering is possible. For all retrofits, it is advisable to check the serial number and tractor data at the BAUER factory.

The rims mounted are always fitted with offset 0 (ET0) as standard. This ensures maximum stability of the rim and long service life of the wheel bearings as the axle stub bearing is also designed for offset 0. With large tyres, this can only be achieved with a swinging axle group.

BAUER poly tankers stand out due to fast filling, high spreading pressure and sturdy pumps. The high-quality standard equipment is complemented by a comprehensive range of accessories.

Our experienced construction engineers develop new components and equipment focusing on well proven technology. BAUER slurry tankers are drawn in full 3D on CAD design workstations, ensuring that spare parts are available even after many years. Test runs and load tests make sure that every prototype is ready for series production.

Your confidence is based on our experience.

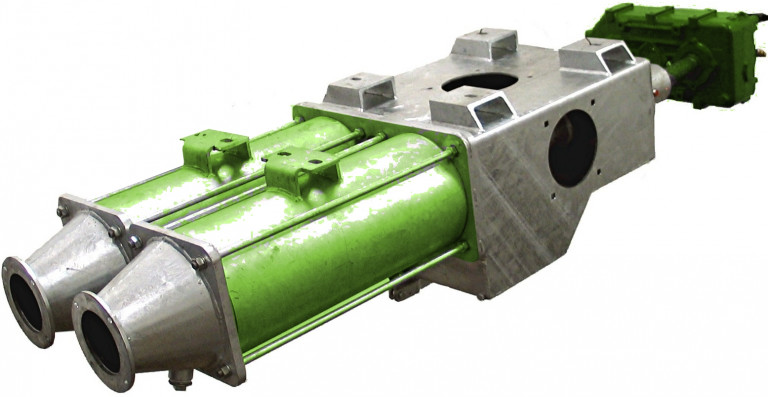

The Bauer eccentric rotor pump is characterized by its high performance data. The extra-large suction box for the tanker insert with a standard foreign body discharge flap protects the tanker from heavy foreign objects.

The pump rotor is manufactured at our own premises. The hollow rotor is made of high-grade steel in a special hot forming process. The low weight of the hollow rotor provides to the pump its smooth running. The whirling process makes the surface perfect, provides for a precise external geometry and a very smooth running surface. This is decisive for high output and low wear. The final surface-hardening serves to refine this perfect surface and to provide a long service life and good resistance.

The pump stator is manufactured at our own premises. A special rubber mix is vulcanized into a steel tube via an extruder. The recipe of rubber mix is appropriate for the use with both slurry and water on account of long experience and of today’s possibilities of materials. After the extruding process, the rubber geometry is hardened in an oil bath offering thus good wear resistance and hence a long service life.

Automatic Filling Stop and Mixing Process as standard

The automatic filling stop is included as standard in the poly tanker. An electronic system detects the maximum filling level and pneumatically or hydraulically switches the slide valves from suction to repumping. Thus, overfilling is impossible. Via an angle sensor, it is possible to pre-set different filling levels in connection with our SIGNO 4.0 control unit.

By switching the three-way slide valve to mixing, the slurry is fed back into the tank. This results in a circulation of the entire contents inside the tank with a strong flow and enormous mixing power corresponding to the pump delivery rate.

Automatic Filling Stop and Mixing Process as standard

The automatic filling stop is included as standard in the poly tanker. An electronic system detects the maximum filling level and pneumatically or hydraulically switches the slide valves from suction to repumping. Thus, overfilling is impossible. Via an angle sensor, it is possible to pre-set different filling levels in connection with our SIGNO 4.0 control unit.

By switching the three-way slide valve to mixing, the slurry is fed back into the tank. This results in a circulation of the entire contents inside the tank with a strong flow and enormous mixing power corresponding to the pump delivery rate.

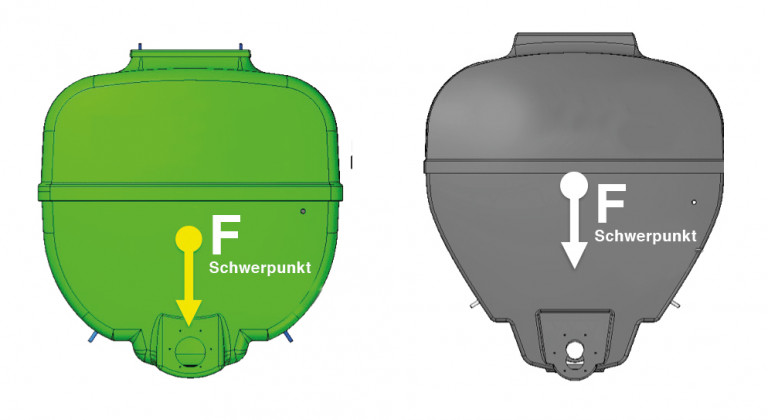

Special colours like Black-Line in noble black give the poly tanker an even more noble touch - your neighbours will be enviously amazed! In addition to the serial advantages, the black tanker offers the possibility of transporting media up to 100°C thanks to even more special material classification.

The pumps are available in various performance sizes and are all self-priming. Corresponding reduction gears are also available for all pumps, increasing the serial control options even further.

A preparation for hose applicator and trailing shoe applicator up to 15m is integrated in the poly tanker AS STANDARD. Retrofitting of these spreading booms is possible. For strip widths from 18m and injection techniques, an optional HP preparation is available, which can be adapted both in the fixed attachment or lifting system CAT 3.

Fast, effective, clean! And without getting off the tractor. With a suction arm (automatic suction), you hydraulically dock the suction line into a suction funnel placed on the slurry pit, the lagoon or the feeder tanker. You start/stop the filling process directly from the tractor via hydraulically controlled suction slides. Different types of suction arms are available.

This vertical load upholding system (SLE System) automatically controls the filling level of the first tank chamber and always allows maximum drawbar load. The SLE system allows best traction on the tractor wheels, thus minimising any damage to the ground and it contributes to a much safer driving behaviour. No wear parts in the system allow for obstruction-proof operation, and the serial best stirring properties of the pump tanker are not affected.

Configure your own individual tanker from a large selection of tyre pressure regulators, the latest control technology and many other options.

In order for the famous Beaufort cheeses to meet the expectations of connoisseurs the world over, it takes family farms like that of André Blanc-Gonnet – and agricultural technology from Bauer.