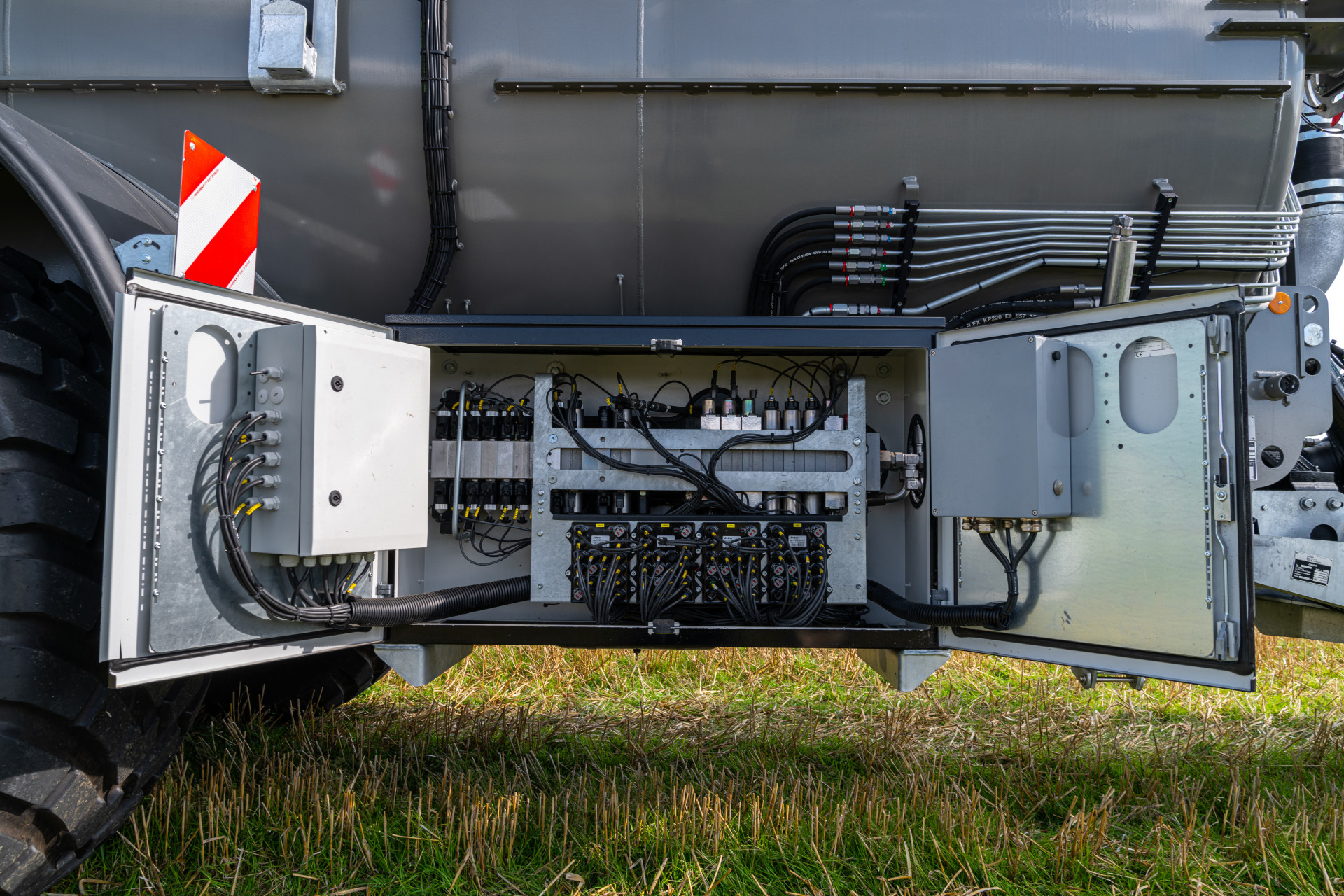

Nowadays, complex tankers and especially those with ground-level spreading technology, require a large number of hydraulic functions. The hydraulic connections available on the tractor are usually not sufficient for a purposeful operation of the slurry tanker. For this reason, from a certain level of equipment, the tanker must be equipped with its own electro-hydraulic control unit. But also, in order to be able to implement automatic sequences which facilitate considerably the operation, the slurry tanker must be able to access to its own individual control logic. There are 4 series of control units available for individual configuration. The Signo4.0‑Comfort, the Signo4.0‑ISOBUS, the I-Control and the seating valve control unit.

High-tech controls are essential especially for precision farming, automatic spreading control systems and NIRS nutrient measurements. We have developed the Signo4.0 control unit on the basis of these latest technologies as well as simple components such as slurry guns. This BUS-based control unit has been developed according to the latest electronic standards and has been specially designed for Bauer slurry tankers. Our internal control department programs and creates this technology in cooperation with the Competence Center ISOBUS, known as CCI for short. As a CCI member, the Bauer Group benefits from cross-company cooperation with other manufacturers in agricultural technology and the Agricultural Industry Electronics Foundation (AEF). This networking ensures both system security and compatibility with tractors and other machines, which the Signo4.0 offers.

The Signo4.0 Comfort offers the know-how of a bus control with the possibility to operate it via intuitive toggle levers. By means of the clearly arranged Comfort terminal, the functions and automatic sequences are controlled directly via toggle levers. Logical positioning and self-explanatory symbols enable quick and safe operation of your slurry tanker. A joystick can also be used. The sturdy aluminium housing is removable and can therefore be stored safely during downtimes. A sequential control of the important operating sequences as well as an optical and acoustic display "tank empty" is included as standard. The control system also automatically detects when one side of the spreading boom is switched off (partial width control) and reduces the application rate of pump tankers by 50% via the distribution slide valve.

The Signo4.0 Comfort offers the know-how of a bus control with the possibility to operate it via intuitive toggle levers. By means of the clearly arranged Comfort terminal, the functions and automatic sequences are controlled directly via toggle levers. Logical positioning and self-explanatory symbols enable quick and safe operation of your slurry tanker. A joystick can also be used. The sturdy aluminium housing is removable and can therefore be stored safely during downtimes. A sequential control of the important operating sequences as well as an optical and acoustic display "tank empty" is included as standard. The control system also automatically detects when one side of the spreading boom is switched off (partial width control) and reduces the application rate of pump tankers by 50% via the distribution slide valve.

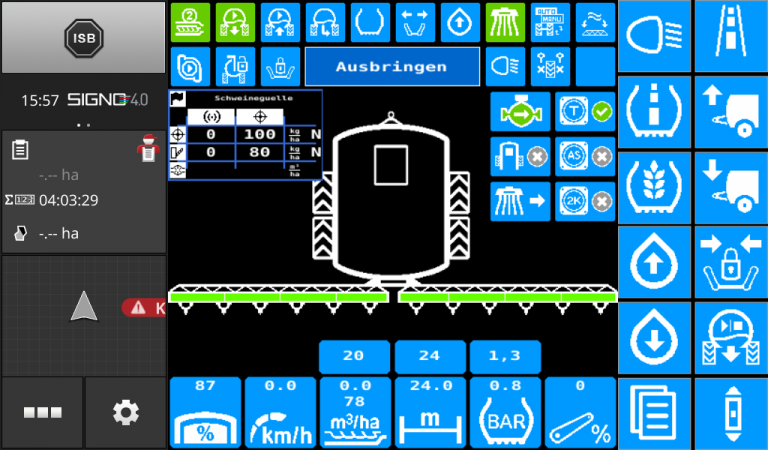

SIGNO 4.0 in connection with ISOBUS standardises the communication, it ensures the compatibility and allows for a control of devices and machines irrespective of the manufacturer. In practice, this means that one single ISOBUS terminal on the tractor replaces many specific terminals of attachments. Of course, the ISOBUS tractor terminal can also be used for tanker operation, provided it is of an appropriate size so that it can be divided appropriately and supports the "12-softkeys" standard. But ISOBUS can do even more: The technology also controls the documentation of individual operations on the field and it manages the data exchange to the PC on the farm. Signo 4.0 ISOBUS is based on the latest generation of job computers with fast and high computing power - this makes reliable processing of the large amounts of data child's play. For operation, 3 terminals and 2 joystick variants are available.

Exact dosing is simple! With the SIGNO electronic portioner, you enter the desired value in m³/ha into your terminal and the system automatically controls the application rate depending on forward speed, PTO speed and strip width. The complex components installed in the tanker, such as inductive flow meters, wheel sensors and actuator, ensure accurate data recognition, transmission and control. Integrated into the SIGNO 4.0 ISOBUS control unit, this provides the basic element for Precision Farming.

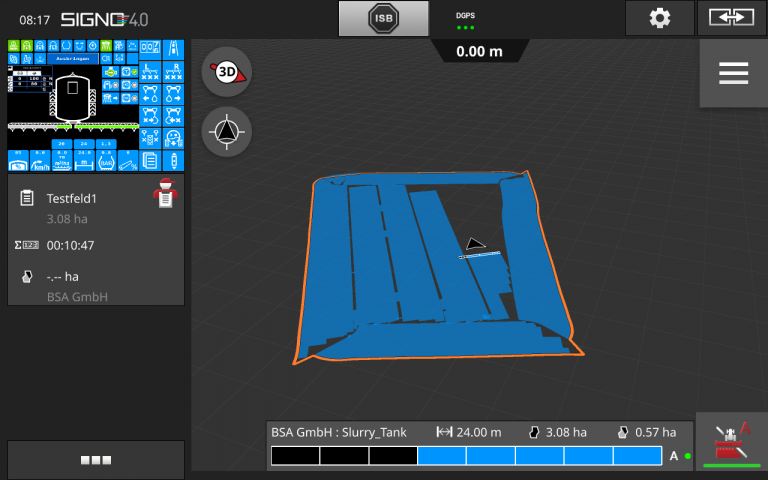

GPS-Precision is the digital tool for efficient slurry spreading and increased precision. These ISOBUS tools support slurry spreading and offer many wide-ranging possibilities, including documentation transmission. Precision Farming requires the Signo 4.0 control unit ISOBUS and GPS.

Parallel Tracking (PT) is a parallel driving aid. The current deviation from the track is displayed visually. For optimal following when fertilising and for crop protection on grassland or in pre-emergence.

Section Control (SC) automatically switches partial width sections from the spreading booms. The headland function allows to block areas for cultivation in order to work the inside of the field first. You can create headlands all around the field or individual headlands at the head ends only.

With this ISOBUS job processing, data is transferred to the home PC via USB, Farmpilot, FieldNav or DIGIS.

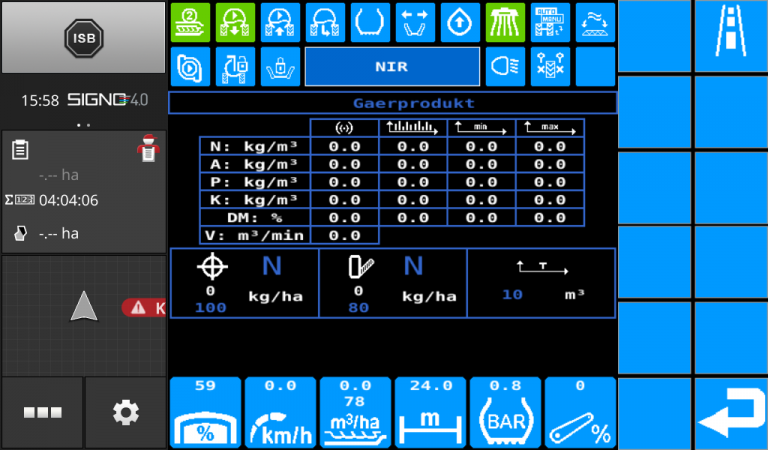

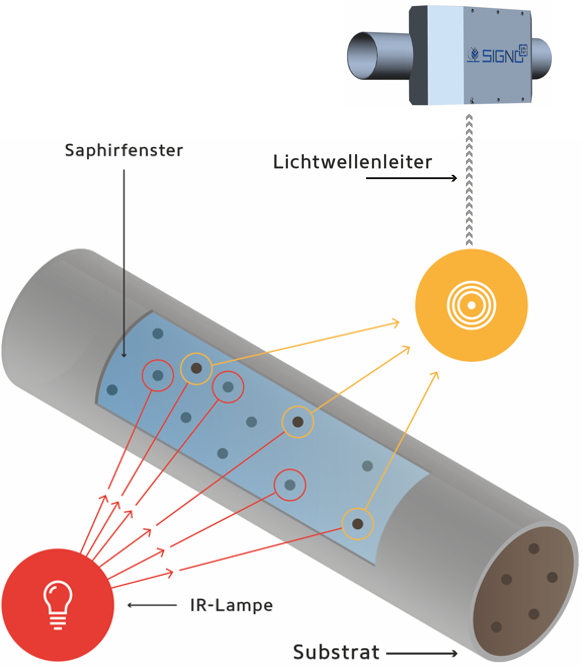

With the SIGNO-ID, fields are fertilised on a nutrient basis and in real-time nutrient values. The SIGNO-ID measures Nges (total inorganic nitrogen), P2O5 (phosphorus pentoxide), K2O (potassium oxide), NH4-N (ammonium nitrogen) and TS (dry matter content). The NIRS (NearInfraRedSpectroscopy) method is one of the most accurate on the market and is based on databases developed over many years which can therefore process pig slurry, cattle slurry and fermentation substrates.

The proven, simple seating valve control is a preselector control that combines simple cylinder functions. The desired function is set via a rotary switch on the control panel and operated with the tractor's hydraulic lever as usual. The control unit is appropriate for combining 2 or 3 cylinder functions if the tractor connections are not sufficient. Our Signo 4.0 control unit is the ideal choice for more complex combinations of functions.