As the costs for high-quality bedding material have increased enormously in recent years, more and more innovative dairy farms are using organic bedding material. This is made of the undigested fibres (feed residues) of the slurry. The BBU concept (BAUER Bedding Unit) separates, dries and disinfects undigested raw fibres from the liquid manure. This means that operating costs can be reduced while at the same time milk production is optimized. Since this is an ecological cycle, not only the costs for bedding material but also disposal costs can be saved. This organic material is produced directly on the farm and is available at all times.

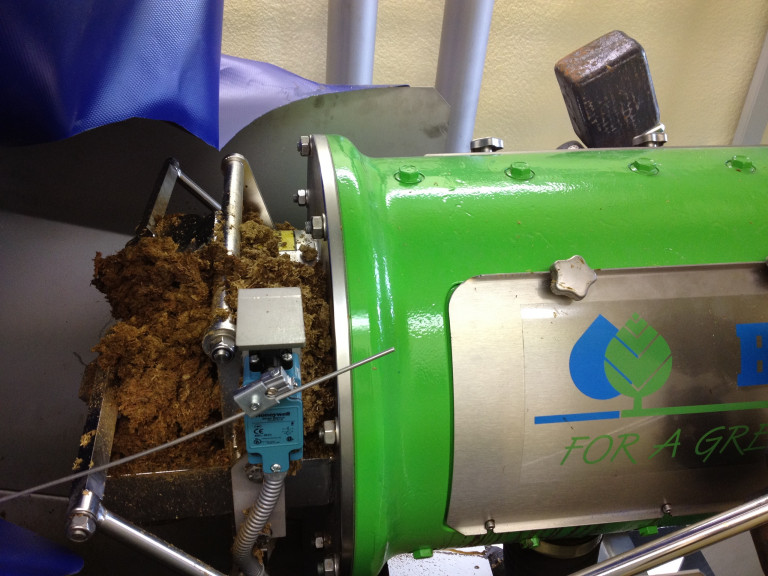

The first step of the process consists of the separation of coarse fibres by a specially designed press screw separator. The solids are mainly undigested residues from the feed, such as fibres from silage or straw. The separator presses out the solids, thereby reducing the humidity level to a minimum. The drying drum is fed continuously via an auger into a specially developed rotating drum made of stainless steel.

The second step of the process takes place in an insulated stainless steel drum. There the solids are subjected to an intensive biological aerobic hygienization process at temperatures of over 65 degrees for several hours, whereby the bacteria are killed or reduced to a minimum. This controlled process guarantees a homogenized product. This treatment of the solids significantly reduces the increase of mastitis pathogens. Laboratory tests from different universities have shown that no detectable bacterial cells were present in the bedding material after this process.

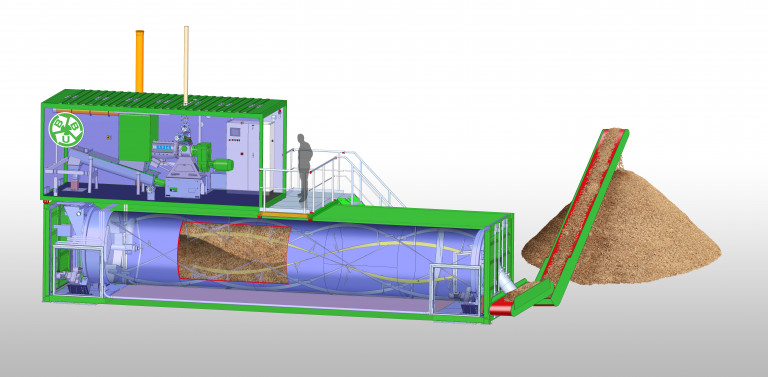

The second step of the process happens in the BAUER composting drum, which is installed in an insulated 40' container. The solids are fed into the drum via a patented flap system so that the drum can be filled to over 70% of its volume. In the drum, the material is continuously mixed and subjected to an intense aerobic process, during which air is sucked out of the drum to remove moisture from the system. For an optimal composting process, the air temperature is kept at around 65-70°C. A homogeneous product is produced by a stable, continuous process.

Thanks to the new discharge system the drum can be filled to 70% of its volume, this means a daily production of up to 46m3 of bedding material.

In order to ensure the fully automatic controlled operation, a special control unit has been developed, which guarantees a constant dry matter content of 36-38% at the separator outlet.

The whole unit as well as the single components can be controlled via the generously dimensioned touch screen panel. Data such as temperature and all setting parameters of the unit can be stored on memory cards over a longer period of time in order to ensure traceability. Furthermore, peripheral devices can also be controlled.

The process is completely automated. The slurry is pumped from the collection tank into the press screw separator. The separated solids are fed to an auger, from where they are transported to the stainless steel drum, where an aerobic process begins. This happens at a temperature of 60 - 75 degrees Celsius without the supply of external energy. The biological process is monitored via temperature measurements and regulated by the air flow. The Bauer Group offers the right size for every business:

BBU 400

Production of organic bedding material per day

BBU 1000

Production of organic bedding material per day

BBU 2000

Production of organic bedding material per day

There is always a lot going on at Fragner, located in Feuchtwangen, Bavaria. Four generations live and work under one roof, but the Fleckvieh cattle are clearly in the majority.

We scrape the slats twice daily and fill the stalls with new bedding using the spreading machine at the same time. About 50 percent of the manure is processed with the BBU. The easy process for making the bedding hygienic and of course the unbeatable comfort of the material for the cows were major factors in favor of the BBU. Plus, the cell counts have gone down considerably, which is very positive for the health of the animals.

Verena Hußmann