With the invention of the RAINSTAR more than half a century ago, BAUER revolutionized the world of irrigation. A lot has happened since then. BAUER has not rested on its laurels, but has worked constantly to further develop the hose reel irrigation machines. Through innovations such as the introduction of turbine technology or the production of our own gearboxes, we were able to further expand our lead and create enthusiasm worldwide. Decades of experience in the field have given rise to new technologies and to today's widely ramified BAUER RAINSTAR family. BAUER hose reel irrigators are easy to operate and stand for robust construction and a long service life. Even under the most difficult conditions. Every customer will find just the right solution from among the 100 models on offer.

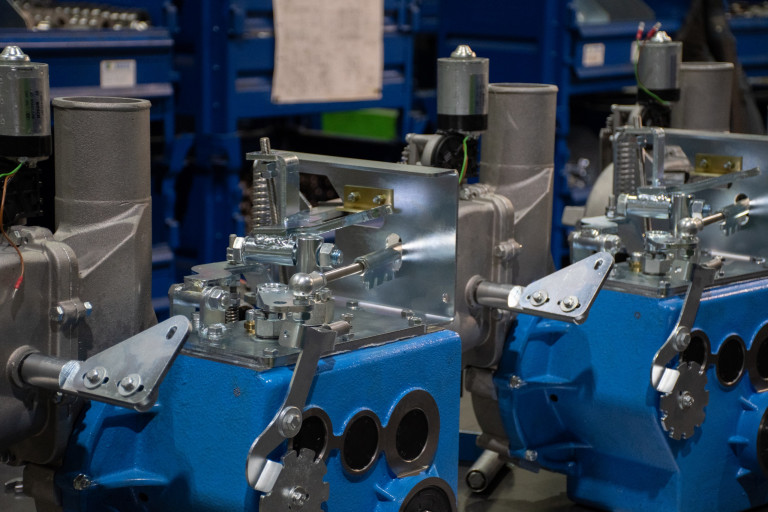

For decades, BAUER has successfully employed the practice of insourcing to ensure quality, and we are the only manufacturer of reel irrigation machines to follow this principle. Instead of purchasing individual parts from all over the world, key components such as controls, gearboxes, turbines, polyethylene pipes, etc. are manufactured internally at the BAUER plant by specialists trained in-house. In this way, we offer our customers the highest quality and precision. In return, they give us what we value most: their trust.

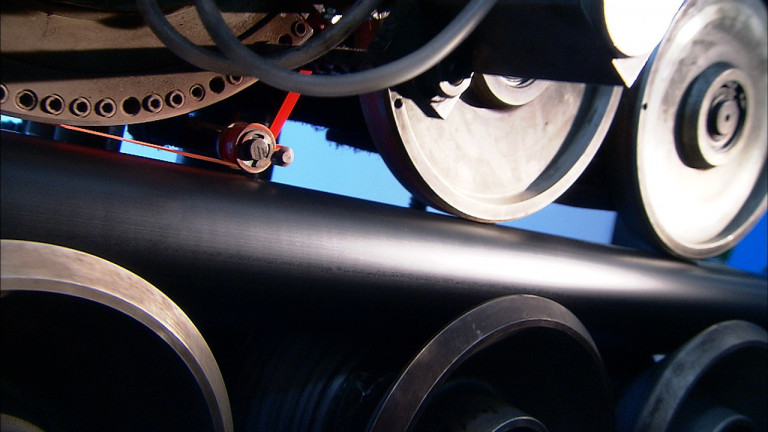

The polyethylene pipe is one of the key components of a reel irrigation machine. Therefore every single PE pipe is produced by BAUER under the strictest quality specifications at the Voitsberg plant. We pay close attention to the correct mixture of the granulates and only accept the best quality. This is why BAUER PE pipes have an excellent reputation worldwide and are known for their exceptional resilience and long service life. Due to the independence and flexibility of our own production, it is possible to adjust the wall-thickness of every single PE-pipe in order to achieve low pressure loss and to save energy. Without compromising on durability, of course.

All steel parts of our RAINSTAR series are hot-dip galvanized, which means optimal corrosion protection for our machines. Apart from the fact that galvanized steel components are durable, strong and weather resistant, they are also 100% recyclable. In order to reduce transport distances, we mainly cooperate with galvanisation plants near our production facility in Voitsberg, which we see as a further contribution to saving resources.