Modern agriculture and environmental protection don’t have to be contradictions. To the contrary: Innovative agriculture is a key part of a meaningful, long-term concept for a fully sustainable world.

We at Bauer have made it our goal to focus our company on sincere sustainability and to develop technologies that live up to our responsibility for the planet. So that we can leave sufficient resources for future generations to enjoy good lives.

According to our philosophy “For a green world,” we recognize our responsibility for the environment. Wherever possible, we take measures to conserve resources and build sustainable processes. This applies to our manufacturing methods as well as our products and solutions. We are also aware that we have not remotely exhausted all the possibilities. Step by step, we must cultivate the ground for a sustainable future.

With this in mind, everything we do is driven by the thought of a truly circular economy. Recycling and upcycling are not just buzz words to us, they are built into our processes in very concrete ways. Our product portfolio includes energy-efficient and water-saving control technology as well as systems for transforming manure into valuable bedding, thereby actively contributing to CO2 reduction. Bauer products are famous the world over for their long service lives.

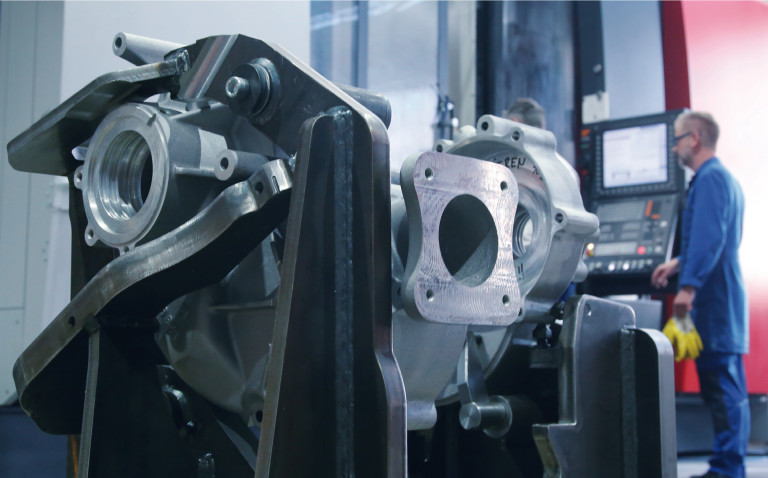

The high manufacturing depth at our factories helps reduce transports and the associated environmental impacts, such as CO2 emissions and noise. Our partners for the supply of raw materials, components and services are drawn from the local region whenever possible. This applies, for example, to our galvanizing plants as well as the foundries we work with.

Consistent compliance with the high environmental standards of Austria is a given for us.

We are also working continuously to increase the level of digitalization in our production, which will help us ensure that resources and materials are used efficiently.

As an industrial enterprise, we need lots of energy. It was therefore clear from the start what we had to do. In 2017, we installed a 2.3 megawatt photovoltaic system with an annual output of about 2,600,000 kWh. This corresponds to the average electricity consumption of 685 households. The best part: We generate 100 percent of the electricity we need every year at the Voitsberg site with the power of the sun, making us energy independent.

But we didn’t stop there: As part of this investment in the future, we also carried out extensive thermal renovations at our Voitsberg site. In some cases, our walls and roofs feature twice the insulation thickness that is typical in the industry. And that really pays off: The total energy demand of 4.2 million kWh was decreased by 70 percent. Just the insulation of the facades reduced the CO2 emissions by 705,000 kg. The photovoltaic system will save another 1,690,000 kg of CO2 per year.

Power generated by our photovoltaic system

Kilograms of CO2 savings through our photovoltaic system & thermal renovations

Energy savings through the PV system

It is clear to us that whenever human mobility is facilitated by machines, emissions are fundamentally unavoidable. However, our goal is to keep these emissions as low as possible.

One measure in this direction is to keep air travel to a minimum. We are able to do this by maintaining our own sales offices in many parts of the world with competent local employees to represent us. Thanks to virtual communication tools, we also have a direct line to our global partners and customers at any time.

Our mission to reduce emissions has also given rise to a continuously expanding fleet of electric vehicles. Charged up with our own solar electricity, of course.

The long lives of Bauer products are legendary. In other words, we are often the ones standing in our own way. After all, many customers use their machines for as long as they continue to work, rather than buying a new one. And that can go on for decades. But that’s just how we like it. Because satisfied customers are essential. Plus, this attitude reduces the impact on our planet.

Long-lasting products are critical for a sustainable world. The longer a product lasts, the fewer resources are consumed. It’s a good thing that the principle of durability has been firmly anchored in our company DNA from the very start.

Slurry, or manure, is a valuable substance that is produced in large quantities every day on the farm. It is the connecting element in the operating cycle of the farm and can be utilized in many advantageous ways. It offers a unique opportunity to practice sustainable recycling and upcycling as part of a farming operation. Bauer slurry technology supports farmers in this process.

The slurry separator has a key role to play here since the separation of solids and liquids opens up many new and useful possibilities for the slurry. For example, the separator can produce organic bedding from the farm’s own manure. This eliminates the delivery of externally produced bedding and the associated emissions. It also takes care of disposal of the manure. Another advantage: The raw material for the organic bedding is produced fresh every day. A never-ending cycle.

The primary purpose of agriculture is to feed people. In view of the rising world population, however, this is only possible by increasing yields. One reliable way to improve the harvest is irrigation. However, there is no losing sight of the fact that water is a scarce resource in many places. The art here lies in using this resource as efficiently and precisely as possible so as not to waste even the smallest drop of this precious liquid.

This is accomplished with smart tools like VRI (variable rate irrigation) or SmartRain, which help farmers precisely dispense the available water. All carefully adapted to the specific crop, soil conditions, growth phase and climate. Unused areas or paths can be exempted, and different crops can be automatically given the correct amount of water even within the same irrigation process. Modern irrigation pulls out all the stops. This is important since every drop counts.